EP Armory 80% AR-15 gen1 lower receiver review

This is a review of the discontinued gen 1 receiver. For the current gen 2 80% lower receiver from EP Armory click here.

EP Armory 80% AR-15 lower receiver

Price - $50

Material - Reinforced polymer

Finish - integrated into plastic

Color - black

Rear pocket - completed

Trigger guard - integrated

Engravings - Safe/Fire/Auto

Notable features - Jigless design, safety selector stops

Works with the 80% Arms Universal Easy Jig - yes

Works with the Modulus Arms Jig - yes

One of the big selling points of this 1st gen EP lower is supposed to be the jigless design (no longer the case with gen2 and cause ATF raid) but I had no interest in making a hacked up receiver with a Dremel tool so I used this lower in my Easy Jig. I believe a lot of complaints about this lower are due to the hack job a jigless design encourages. However some criticisms are not due to that and I will cover that later. It should be noted that this is the 80% lower that the BATFE later decided was not an 80% lower. EP Armory has changed their design to address those concerns but it appears virtually the same as this generation.

First impressions:

This is a well made polymer based lower. You can tell it is reinforced by both look and strength of the material. This is a strong polymer and squeezing shows no signs of give. The rear pocket is already milled (or formed) out which I always appreciate. Since the color is set into the plastic no additional finishing is required. The original EP Armory lowers came in several colors and the new model does as well.

Fitment to the universal Easy Jig:

Good

Fitment to the Modulus Arms Jig:

Good

Ease of machining:

Polymer is very easy to machine and you can zip right through it with the 3/8" drill bit and the 1/4" end mill. It should be noted that if you go too fast the drill bit will heat up and melt the plastic. Be sure to allow the drill bit to cool down occasionally to prevent overheating and melting. I did not need to use any cutting fluids when machining this receiver.

Final thoughts:

This lower was very easy to complete and I like that the polymer is very strong and requires no additional finishing. The hole for the pistol grip screw is not threaded but it will be threaded by the pistol grip screw at the time of installation. I did not have any luck trying to be fancy by using a tap and die. I recommend starting the hole with just the screw for a few threads and then remove the screw and install the grip. This will help ensure you are threading the screw in straight which is hard to see with the grip in place.

I do have two issues with this lower. First, the left side of the receiver's ("driver's side" if you're a right-handed shooter) rear takedown hole is drilled too far back. Not a lot but it's clearly skewed when you put the pivot pin through. Both receivers I bought had this problem and I have read of others having this problem as well. It's fairly easy to fix if you just egg-out the hole forward using a 1/4" drill bit. This makes the hole oblong but since the rear lug of the upper receiver holds it straight it's not a problem. I did this same adjustment to the latest Polymer80 G150 I reviewed.

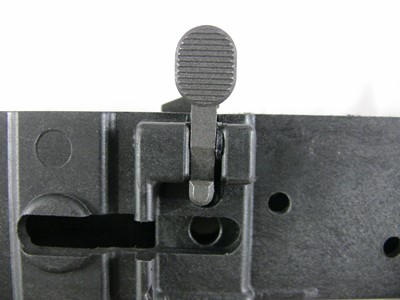

The second issue is the opening for the bolt catch where the pivot pin drives through is too wide. I had this same issue with the James Madison Tactical lower and the Polymer80 G150 (gen1) lower. This causes the bolt catch lever to slop around. That would only be annoying except for the fact that this slop causes the bolt catch not to engage sometimes. What happens is the bolt catch will get pushed back in the opening and then won't catch on the magazine's follower. You need the bolt catch to be pushed forward in the opening so this doesn't happen. Again, both both receivers I purchased were like this.

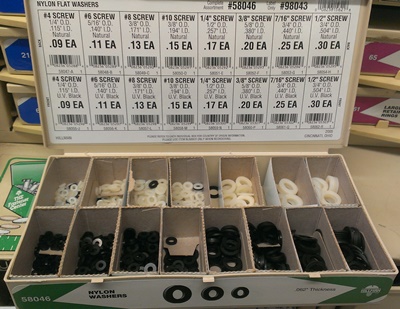

I fixed the issue by installing a thin plastic washer on the roll pin between the bolt catch and the right side of the receiver where the pin goes through (see photo below). At a gun shop I noticed a commercially made Exatar pistol polymer lower had a similar remedy so maybe it is a common problem for polymer AR lowers. I had to sand the washer down until it made the bolt catch snug enough to engage the magazine follower but loose enough not to bind in the channel. If you need a washer like this they can be found in the "Hillman" boxes at your local hardware store. They have both black and "natural" which is an off-white. The Hillman box number is 58046 "Nylon Washers" and the ones you want are 58047-A (natural) and 58055-J (black). These are the two washers in the front and back rows, furthest to the left in the photo.

At $50 this is a very good value in a well-built polymer lower receiver. The multitude of colors is a plus if you want something besides black. Hopefully the two mentioned issues will be fixed in the next version of this lower but even so it is only a little extra work once you know what needs to be done.

80% lower receiver comparison chart