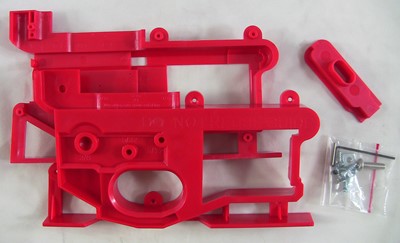

Ares Armor Polymer80 G150 (gen 1) 80% AR-15 lower receiver review

Ares Armor 80% AR-15 lower receiver

also sold by the manufacturer of this lower

Polymer80 G150 80% AR lower receiver

Price - $75-80

Material - polycarbonate (new generation is reinforced nylon)

Finish - integrated into receiver

Color - semi-gloss black (new generation is matte)

Rear pocket - completed

Trigger guard - integrated

Engravings - none

Notable features - metal insert for pistol grip screw, threaded bolt catch pin

Works with the 80% Arms Universal Easy Jig - yes

Works with the Modulus Arms Jig - yes

NOTE: This review is of the first generation G150 receiver which has now been replaced by a next generation (Phoenix) lower that is made of nylon based material.

Like the Model T, you can get these lowers in any color you want as long as it's black. The lower can be Cerakoted/Duracoated or hydrodipped after machining. The Ares Armor/Polymer80 G150 lower comes with it's own jig which I did not use and instead opted to use my Easy Jig further. In addition to the jig, the lower comes with a pistol grip screw and square nut insert for the pistol grip screw to thread into. The bolt catch pin is a metal dowel with a separate 6-32 Allen head cap screw that threads into the receiver to retain it. Unlike other lowers the Polymer80 kit comes with three drill bits and a 7/16" end mill.

First impressions:

This is the first lower I have seen with a semi-gloss finish. The polymer does not appear to be reinforced with any fibers and according to Polymer80 it is 100% polycarbonate. It doesn't seem to be as strong as the reinforced receivers and I am able to flex the magazine well by squeezing it with my hand (again, this is not the new Phoenix version which is reinforced nylon). The receiver itself has extensive reinforcements to it though. The magazine well has an extra angle in it which may be cosmetic or may be functional, I'm not sure which. The trigger guard is very roomy and should be no problem for even large gloved hands. Overall the receiver is a good bit lighter than other polymer receivers. Even without cutting the area between the already completed rear pocket and the fire control group pocket the finished receiver weighs 115g versus 153g for the JMT lower (about a 1 1/3 ounce difference).

Fitment to the universal Easy Jig:

Good

Fitment to the Modulus Arms Jig:

It would fit but the buffer support will not thread in

Ease of machining:

Per usual, the polymer proved to be very easy to machine with the 3/8" drill bit and the 1/4" end mill at 1720 RPM. It should be noted that if you go too fast the drill bit will heat up and melt the plastic. Don't be tempted to go too fast and allow the drill bit to cool down occasionally to prevent overheating and melting. I did not need to use any cutting fluids when machining this receiver.

Final thoughts:

The Ares Armor (Polymer80) G150 kit is a good value as it comes with not only the lower and jig but the drill bits and end mill to finish it. The regular price of this kit is $90 plus $10 flat rate shipping but I got mine on sale for $70 plus $10. The new version is currently being sold for $80. The lower was very easy to machine and worked with the original Easy Jig if you are willing to make modifications for the receiver's reinforced areas but the new universal Easy Jig fits without modification.

Like the other two polymer lowers I have completed (EP Armory gen1 lower and James Madison Tactical lower) the bolt catch slot was too wide. This causes the bolt catch lever to slop around. That would only be annoying except for the fact that this slop causes the bolt catch not to engage sometimes. What happens is the bolt catch will get pushed back in the opening and then won't catch on the magazine's follower. You need the bolt catch to be pushed forward in the opening so this doesn't happen.

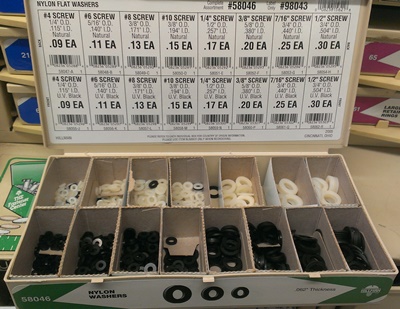

I fixed the issue by installing a thin plastic washer on the roll pin between the bolt catch and the right side of the receiver where the pin goes through (see photo below). At a gun shop I noticed a commercially made Exatar pistol polymer lower had a similar remedy so maybe it is a common problem for polymer AR lowers. I had to sand the washer down until it made the bolt catch snug enough to engage the magazine follower but loose enough not to bind in the channel. If you need a washer like this they can be found in the "Hillman" boxes at your local hardware store. They have both black and "natural" which is an off-white. The Hillman box number is 58046 "Nylon Washers" and the ones you want are 58047-A (natural) and 58055-J (black). These are the two washers in the front and back rows, furthest to the left in the photo.

Installing the cap screw into the bolt catch area required a little bit of skill. I used the included Allen wrench with the long section to initially thread the screw into the plastic. Apply some pressure to the end of the wrench so it bites into the plastic and threads the hole. Without pressure it will never grab. Start the wrench with the smaller end pointing towards the trigger guard to maximize the amount of turn you get before the smaller end hits the top of the receiver.

I did have to do some additional machining work on the lower to get some of the detents to work. While the front pivot pin detent went in smoothly the rear takedown pin detent was a little too tight. I had to use a drill bit and carefully ream it out a little to get the detent to fall in and out as it should. I also had to do a good bit of reaming of the buffer tube detent hole. I believe this hole should be 1/4" but I used a 17/64" bit to remove enough material for the detent to slide up and down as it should. For all reaming with the drill bits I did not used a drill but instead held the bit with a set of Vice grips and turned it by hand. I've found this additional fitting is not unusual with polymer lowers.

80% lower receiver comparison chart