Polymer80 WarrHogg LR-308 AR-10 80% AR lower receiver review

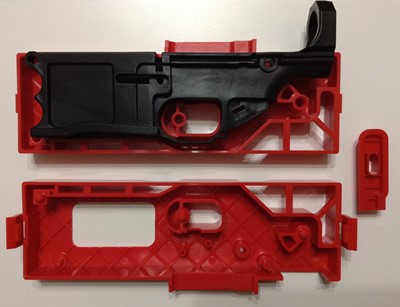

Polymer80 WarrHogg LR-308 AR-10 80% AR lower receiver

Price - $100

Material - reinforced nylon

Finish - integrated into receiver

Color - matte black

Rear pocket - completed

Trigger guard - integrated

Engravings - none

Notable features - metal insert for pistol grip screw, includes proprietary jig, drill bits and end mill

Works with the 80% Arms Easy Jig - no

Works with the Modulus Arms Jig - unknown (the Modulus Arms 308 jig is not yet available)

This is the 308 caliber version of the G150 receiver sold by Polymer80 and is named WarrHogg. As most aftermarket 308 caliber AR receivers are this one is based on the DPMS LR-308 pattern. Like the G150 it uses a reinforced polymer that can be Cerakoted/Duracoated or hydrodipped after machining. Also like the G150 it comes with its own proprietary jig, drill bits and an end mill for completing the machining. In addition to the jig and tool kit this lower, like the G150, comes with a screw and nut for the pistol grip. This eliminates the need to try and thread a machine screw into a polymer base. Unlike the G150 the WarrHogg does not come with a dowel and cap screw for the bolt catch screw. This is because the DPMS pattern lower parts kit comes with a special screw for the bolt catch and it's unnecessary to ship one with the lower.

Previous machining I have done to the G150 receivers were done in the 80% Arms Easy Jig but this lower will not fit in the 80% Arms 308 jig which is not universal. It may fit in the Modulus Arms 308 jig which is a universal design but I do not own one of those jigs as they are not yet available. I suspect they will fit though as their AR-15 jig fits the G150 lower. As such I have yet to machine this lower but I was still able to check the fit with a DPMS upper receiver and with Magpul and C Products magazines.

Here is the Polymer80 YouTube video showing how to mill out the G150 using the included jig, drill bits and end mill using a drill press with an X-Y vise. The machining of this lower with a drill press and the included jig will be similar. Be sure to also read the instructions for this lower on the Polymer80 website.

First impressions:

The WarrHogg, like the G150, is made from a very strong reinforced polymer material. Like most DPMS pattern lower receivers, and the G150, the WarrHogg has an integrated trigger guard. The jig is different than the G150 jig because it uses no screws at all to hold it toghether. Instead there are two heavy plastic clips on both ends of the jig which is a lot more convenient.

My jig had a very slight bow to it which gave a small gap on the top of the receiver. When I machine out the lower I will just squeeze the jig together and then use a piece of tape to keep the gap closed.

Being polymer the receiver is a good bit lighter than an aluminum receiver. Unmachined an 80% Arms 308 lower weighs 435 grams as compared to the 224 grams of the WarrHogg. That will change after machining and I'll add those numbers at a later date. But for now that 211 gram difference is about 7.4 ounces or nearly a half pound.

Fitment to the 80% Arms 308 Jig:

No

Fitment to the Modulus Arms 308 Jig:

Unknown but likely

Ease of machining:

As stated previously I have not to machine this lower but I have machined the same material in the Polymer80 G150 lower and it gave no problems. Machining polymer is much easier and faster than machining either 6061 or 7075 aluminum and that isn't going to change for this lower. As always it should be noted that if you go too fast the drill bit will heat up and melt the plastic. Don't be tempted to go too fast and allow the drill bit to cool down occasionally to prevent overheating and melting. I do not use any cutting fluids when machining polymer.

Final thoughts:

I'm anxious to get out and machine this lower. I know the polymer to be strong and the weight savings will be welcome in an LR-308/AR-10 build which is always heavy. To my knowledge this is the only polymer 308 80% lower on the market though James Madison Tactical does have one under development. The Polymer80 receivers are always a great value as they come with not only the lower and jig but the drill bits and end mill to finish it. I tested a Magpul PMAG 25 round window magazine and a C Products straight body stainless magazine and both dropped free. Even if they hadn't polymer can be sanded/filed down to make them drop free which is nice for the home builder. Fitment to a DPMS brand upper receiver was good with no wobble and a slight gap between the receivers.

I did not have the issue of the bolt catch slot being too wide as I did with the first generation G150 and some other polymer lowers. It did take some doing to get the buffer tube aligned and threaded in. You have to use caution when threading in a metal tube into a polymer receiver as you could pretty easily cross thread them. Take your time and check the angle from both the side and the top to make sure it is aligned in directions. Installing the bolt catch screw was very easy as this was already threaded. The only extra work I ran into was the front pivot pin detent hole was much too shallow. The spring stuck past the receiver probably 3/8" when it should have the spring end about halfway in the pivot pin hole as viewed from the side of the receiver. I remedied this by drilling out the hole the rest of the way with a 3/32" drill bit. Not a big deal but just make sure you check yours before attempting the pivot pin installation. Here is a YouTube video someone made that shows installation of the pin. No real tricks shown other than what I just figured out on my own. My pivot pin installation tool did not work because the LR-308 pattern has the detent inside the receiver ear and not outside as on the AR-15 type receiver.

As with the gen1 G150 and some of the other polymer lowers I have used (80% and commercial) I did have to do some additional machining work on the lower. Be sure to clean up any excess plastic flash (the random bits of stray plastic left over from the molding and machining process). You don't want these bits to get stuck in one of your spring or accumulating in your fire control group. It's also a good idea to check/ream the front and rear detent channels which is good practice on any polymer lower because you don't want to find out too late the channel is slightly undersized.

The WarrHogg is another great offering from Polymer80 and offers a strong DPMS pattern lower with a jig and bit set for only $130. I also like the look of the lower and the fact that it is lightweight. If you're in the market for an LR-308 build you should definitely consider using the WarrHogg for your receiver.

80% lower receiver comparison chart