James Madison Tactical 80% AR-15 lower receiver review

Price - $100 (NO LONGER AVAILABLE)

Material - Reinforced polymer

Finish - integrated into plastic

Color - matte black (also available in FDE and OD)

Rear pocket - not completed

Trigger guard - integrated

Engravings - Safe/Fire, Made in the U.S.A., CAL MULTI, JMT logo on right side of magwell

Notable features - safety selector stops, brass insert for pistol grip screw, magwell gripping

Works with the 80% Arms Universal Easy Jig - yes

Works with the Modulus Arms Jig - yes

This is the first generation JMT lower and they have now come out with a gen2 model which has more reinforcements and some other minor changes. Specifically the JMT logo has been moved and webbed Magpul PMAG type reinforcements have been made to the magwell. The JMT logo has significantly decreased in size and moved to the new reinforcement above the magwell. The JMT lower comes with its own three piece plastic jig which I did not use and instead opted to use my Easy Jig.

First impressions:

This is a very well made and thought out polymer lower. It is reinforced polymer like the EP Armory lower which makes it very strong. There are a few receiver reinforcements and their gen2 has even more. This gen1 lower has a large JMT logo on the right side of the magwell while the gen2 has a PMAG style webbing design. The pistol grip screw hole has a brass insert which is a nice touch that I prefer to the thread-your-own style on the EP Armory lower. This lower has some other markings which most 80% receivers lack such as the "CAL MULTI" and "Made in U.S.A.". The safety selector is also marked for safe and fire.

Fitment to the universal Easy Jig:

Good

Fitment to the Modulus Arms Jig:

Good

Ease of machining:

Polymer is very easy to machine and you can zip right through it with the 3/8" drill bit and the 1/4" end mill. It should be noted that if you go too fast the drill bit will heat up and melt the plastic. Be sure to allow the drill bit to cool down occasionally to prevent overheating and melting. I did not need to use any cutting fluids when machining this receiver.

Final thoughts:

This lower was very easy to complete and I like that the polymer is very strong and requires no additional finishing as the color is built-in. The rear takedown pocket was not completed so some additional machining was needed for that. During assembly of the parts kit in the lower I ran across two problems. The first, like the EP Armory gen1 lower and the Polymer80 G150 lower, was that the bolt catch pin area was too wide. This causes the bolt catch lever to slop around. That would only be annoying except for the fact that this slop causes the bolt catch not to engage sometimes. What happens is the bolt catch will get pushed back in the opening and then won't catch on the magazine's follower. You need the bolt catch to be pushed forward in the opening so this doesn't happen.

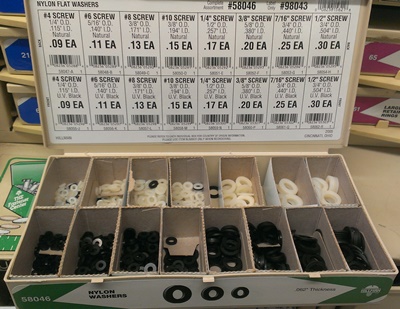

I fixed the issue by installing a thin plastic washer on the roll pin between the bolt catch and the right side of the receiver where the pin goes through (see photo below). At a gun shop I noticed a commercially made Exatar pistol polymer lower had a similar remedy so maybe it is a common problem for polymer AR lowers. I had to sand the washer down until it made the bolt catch snug enough to engage the magazine follower but loose enough not to bind in the channel. If you need a washer like this they can be found in the "Hillman" boxes at your local hardware store. They have both black and "natural" which is an off-white. The Hillman box number is 58046 "Nylon Washers" and the ones you want are 58047-A (natural) and 58055-J (black). These are the two washers in the front and back rows, furthest to the left in the photo.

The second problem was the front pivot pin and rear takedown pin holes in the receiver were too large. I noticed this when I installed the front pivot pin. It had a lot of slop and skewed in all directions as I tried to push it through the receiver. Below is a picture of that. Just to make sure it wasn't the pivot pin I measured the pin with a digital micrometer and it was right at 0.250 inches. The rear takedown pin was also skewed but because of an AR-15 receiver's geometry (narrower in the rear) it was not as pronounced. Once an upper was installed the front pivot pin pushed through quite readily. The rear takedown pin was slightly tougher to get into the upper and through the other side of the lower receiver but with a little wiggling the pin would go through. So until high-speed-low-drag "tactical reassembly" becomes a thing I'm not worried about it.

Due to the receiver reinforcements around the rear takedown pin the use of a tool is necessary to push it back through the receiver for disassembly. Normally a rear takedown pin sticks out of the receiver enough that you can push it in with your finger but that is not the case with this lower.

As polymer lowers go this is definitely on the high end. The price direct from James Madison Tactical was $115 shipped though I got mine from Rainer Arms for $103 shipped (no longer available). This is twice the price of the EP Armory receiver and about 25% more than the Polymer80 (which includes bits and mill). The JMT lower comes with its own jig while the EP Armory does not (Polymer80 does). This was a non-issue for me as I only use the Easy Jig for doing my lowers. The threaded brass insert for the pistol grip was great because I like to try different grips so a metal insert will increase the life of that screw hole. The receiver is heavily reinforced which may give you more confidence in the life and durability of the receiver. I'm usually not wild about companies putting their logo on an 80% lower but their gen2 model definitely makes that much less noticeable. In either case it is a good looking logo and receiver. To me the JMT lower resembles more of a machined billet receiver like the Polymer80 while the EP Armory is more like a standard forged lower in design. Having handled all three I have confidence that any will do the job and a personal choice will have to be based on price, features and overall design.

80% lower receiver comparison chart